OUR WORK

In-house design, engineering and marketing, management of external suppliers to produce any product, treatment or processing, quick delivery, worldwide shipping... These are just some of the services we provide to our customers.

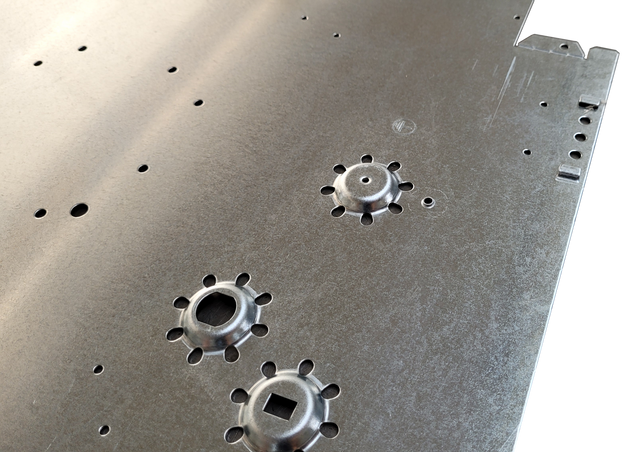

Punching and laser cutting

Our punching machines and laser cutters play a very important part in sheet metal cutting.

With a punching machine, you can deform and cut sheet metal into whatever shape the customer desires, in very short times and at low costs.

Our

Trumpf-Trumatic L3030 laser cutter allows for extremely flexible working. It lets you cut widths five times finer than a punching machine does, meaning excellent finishing, smooth pieces and no burrs.

Bending

After cutting comes bending.

Bending sheet metal is a mechanic process in which the object is deformed by applying force, using specific bending machines.

Our

bending machines can do whatever bending our customers need, with processes and technologies that ensure the utmost quality.

Panelling

An alternative to bending is panelling.

Our Salvagnini P2 paneller, with its automatic cycles of panelling, manipulation and flexibility and its universal bending tools, can bend most panels on the market, satisfying all customer requests.

Its main strengths are the speed at which it bends, the fact it can also do operations like riveting and hanger bolt insertion during the working cycle, and the guarantee that its bends will be repeatable.

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

Welding and punching

At our

welding and punching department, we do manual

MIG, MAG and TIG welding, as well as the automatic variety with the Asea Esab robot, and electric punching.

Rivets, hanger bolts and threaded inserts

Besides welding, there are several operations to be carried out in order to complete the product and improve its functioning:

Riveting: Where welding is not possible or not necessary, riveting is the commonest method for quickly attaching two sheets of metal.

Hanger bolts: Inserting hanger bolts can be done by pressure, using our Haeger, or with a high-tension electrical charge, to weld the threaded bolt to the metal surface.

Threaded inserts: This process is equally important because it allows you to add a thread to thick sheet metals, with the help of an insert tool.

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

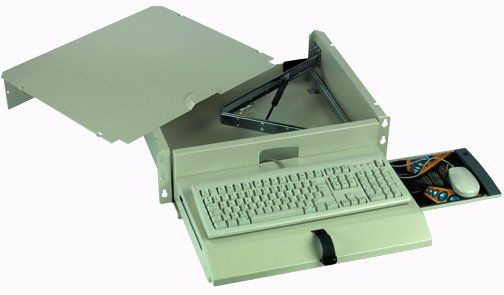

Surface treatments and assembly

We work with the best companies in the sector to provide surface treatments like varnishing, galvanising, screen printing, cataphoresis and many others.

The final phases of work are assembly and packaging.

Gallery of finished products

Via Piave, 16 - 21041 Albizzate (VA) | Tel. +39 0331 993051 |

info@magnoni.it

VAT no. 00184290120 |

Legal information

|

Privacy Policy and Cookie Policy

|

Information policy